3. 3D printing#

Let the adventure continue and turn my creations into real objects with the help of a Prusa 3D printer at the FabLab! The mission? To explore the power and limits of 3D printing.

Installing PrusaSlicer#

PrusaSlicer is a slicing software that turns 3D models into instructions for your 3D printer. Think of it as a translator.

Preparing for printing#

I followed this tutorial to prepare the gcode, using a slicing software. Here it is step-by-step :

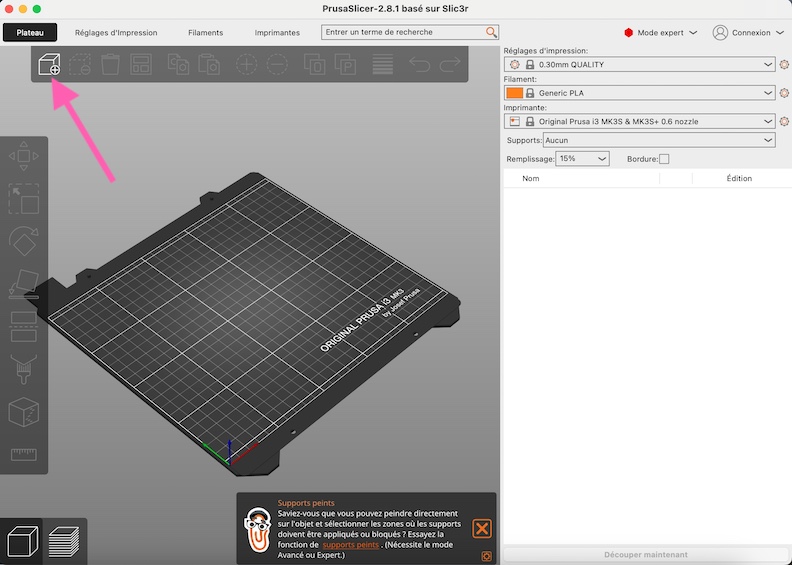

- import a STL file into PrusaSlicer

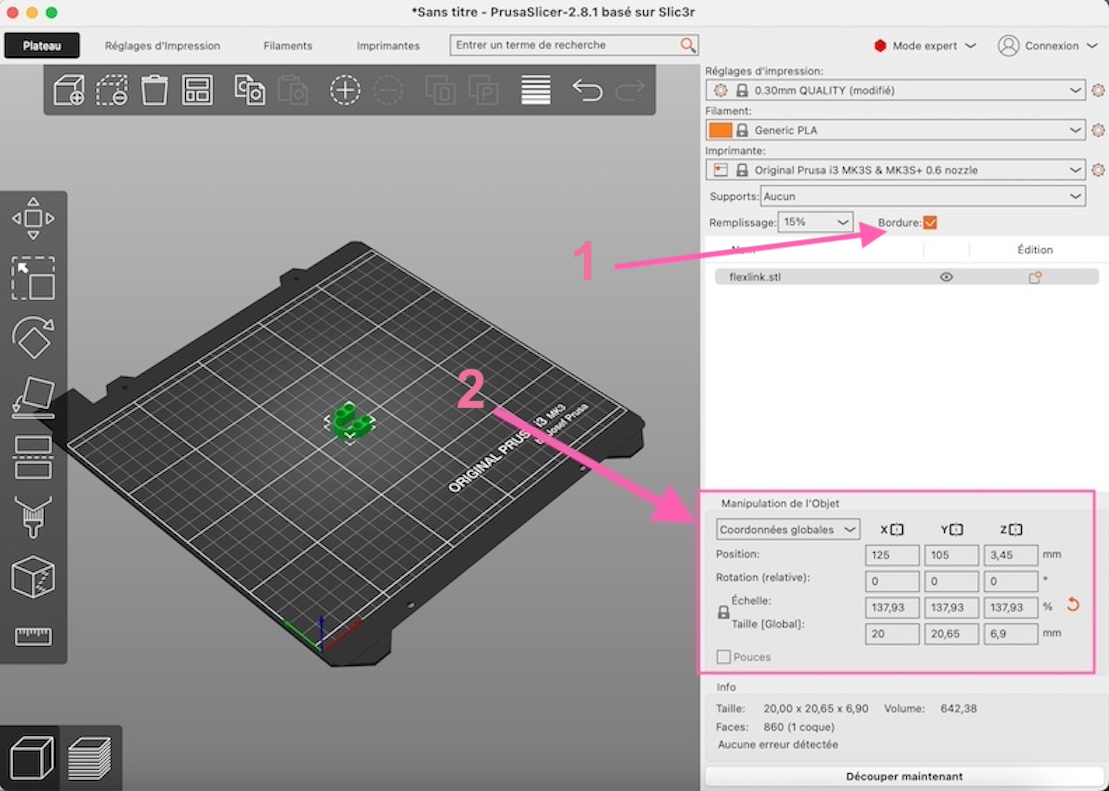

- make modifications (2) and add a brim (1) if needed

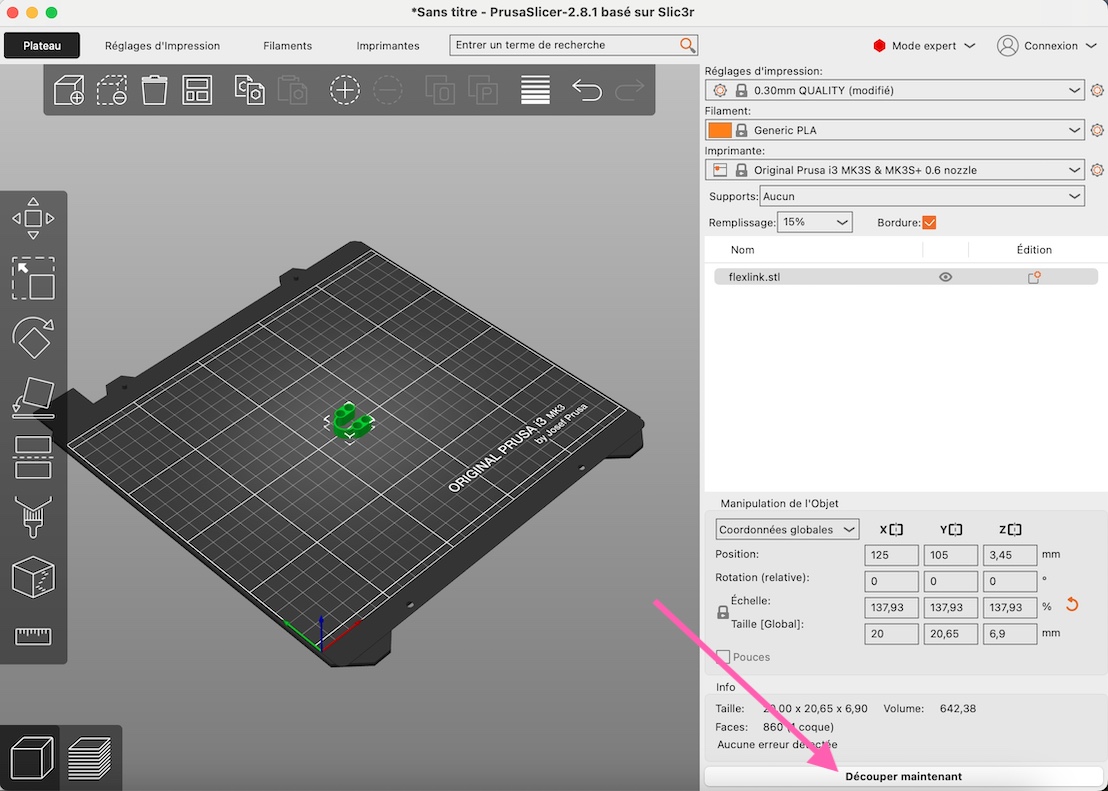

- Click on slicing

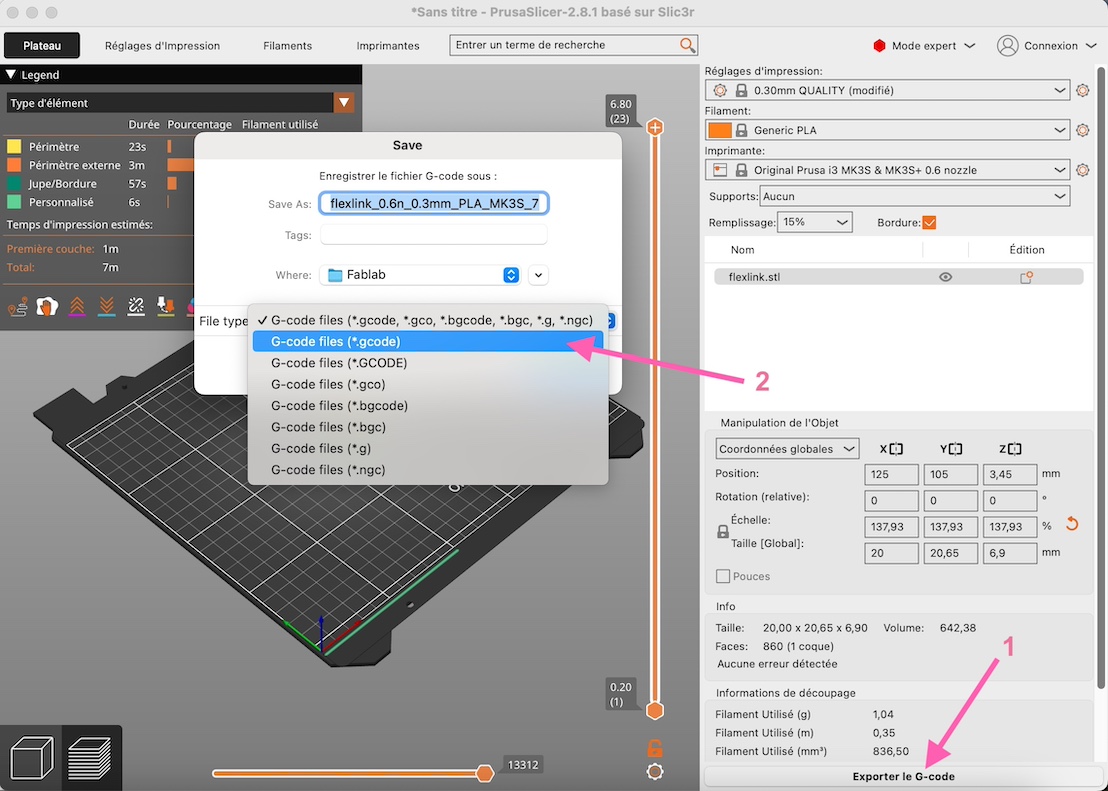

- make sure you export as “.gcode”

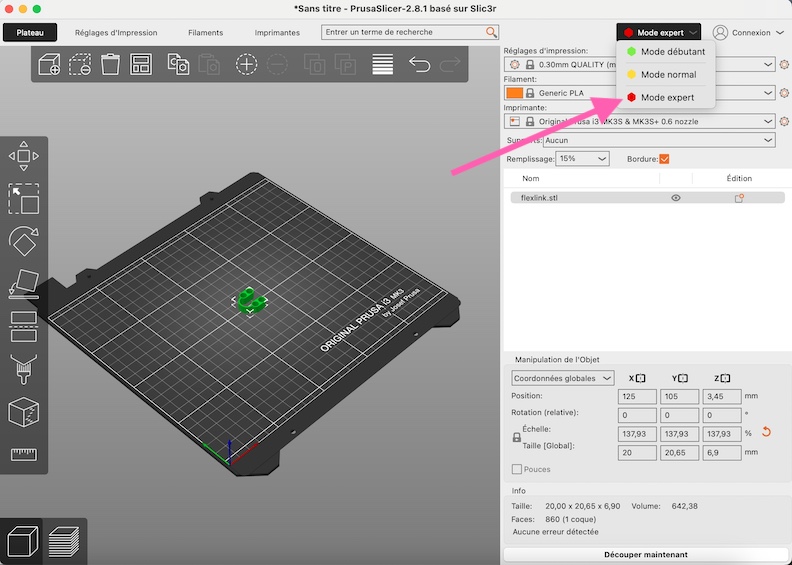

tips : put it in expert mode so you have all the functionalities

At the ULB FabLab :

- make sure the filament is “generic PLA“

- make sure the printer is “Original Prusa i3 MK3S & MK3S+ 0.6 nozzle“

Printing#

It’s finally time to bring the design to life, here is how I did :

- Place the printing plate on

- Clean the plate with the product provided (because greasy fingers can mess up the print)

- Put your “.gcode” file on the SD card (important : the printer doesn’t have any memory, so no SD card = no printing!)

- start printing by selecting the file with the round button on the right of the 3D printer

- once the printing is done, detach your masterpiece from the plate

My 3D printing#

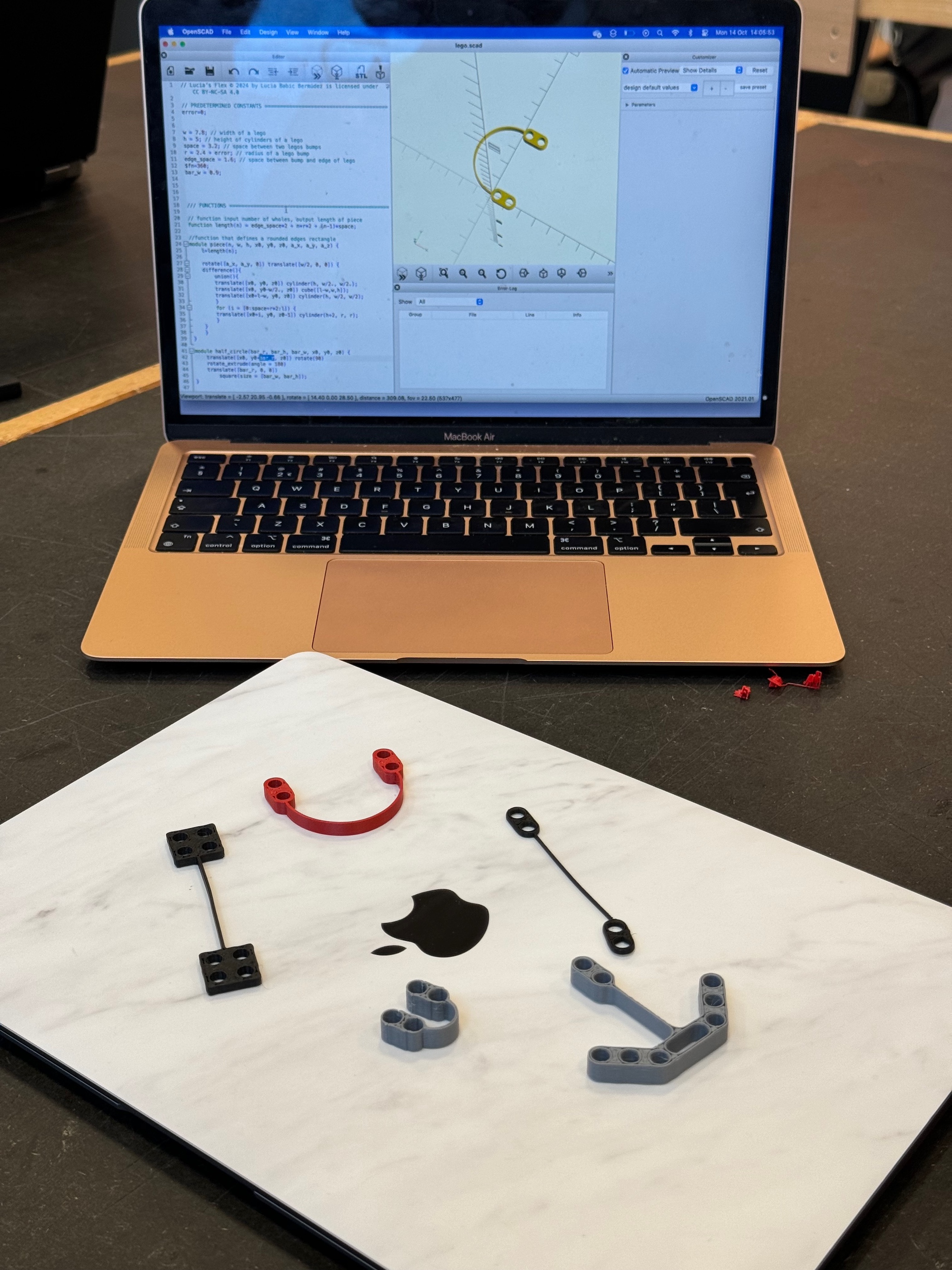

Here is the piece I designed in the module 2 :

And check out the flexlinks printed by my classmates (Lucia & Matilde) and myself :

But let’s not forget the real goal of all this, does my flexlink fit on a LEGO piece? And I’m happy to say that it does!

→Mission accomplished!

Time for the next challenge!